Visy For a Better World

Visy is powering the circular economy, closing the loop between packaging, recycling and remanufacturing

Over 75 years, we've grown to 7,000 employees and 150 global operations - predominately in Australia and New Zealand. Visy proudly remains an Australian family-owned company.

Visy believes materials are not recycled until they’ve been made into new products. We are using recycled content to power Australia and New Zealand’s food and beverage packaging industry. We manufacture anything from cardboard boxes, water bottles, jam jars and food and beverage cans, all using recycled content.

Visy is Australia’s largest recycling company, and we partner with councils across Australia to process approximately 40 per cent of Australia’s kerbside recycling bins.

Our partnerships with councils and our customers are diverting materials away from landfill, cutting emissions and protecting our precious natural resources.

Beyond packaging and recycling, we're proud to support our customers by providing integrated solutions for logistics, packaging supplies, point of sale displays and more.

Recycling

Packaging solutions

Logistics

Retail Services

Explore more

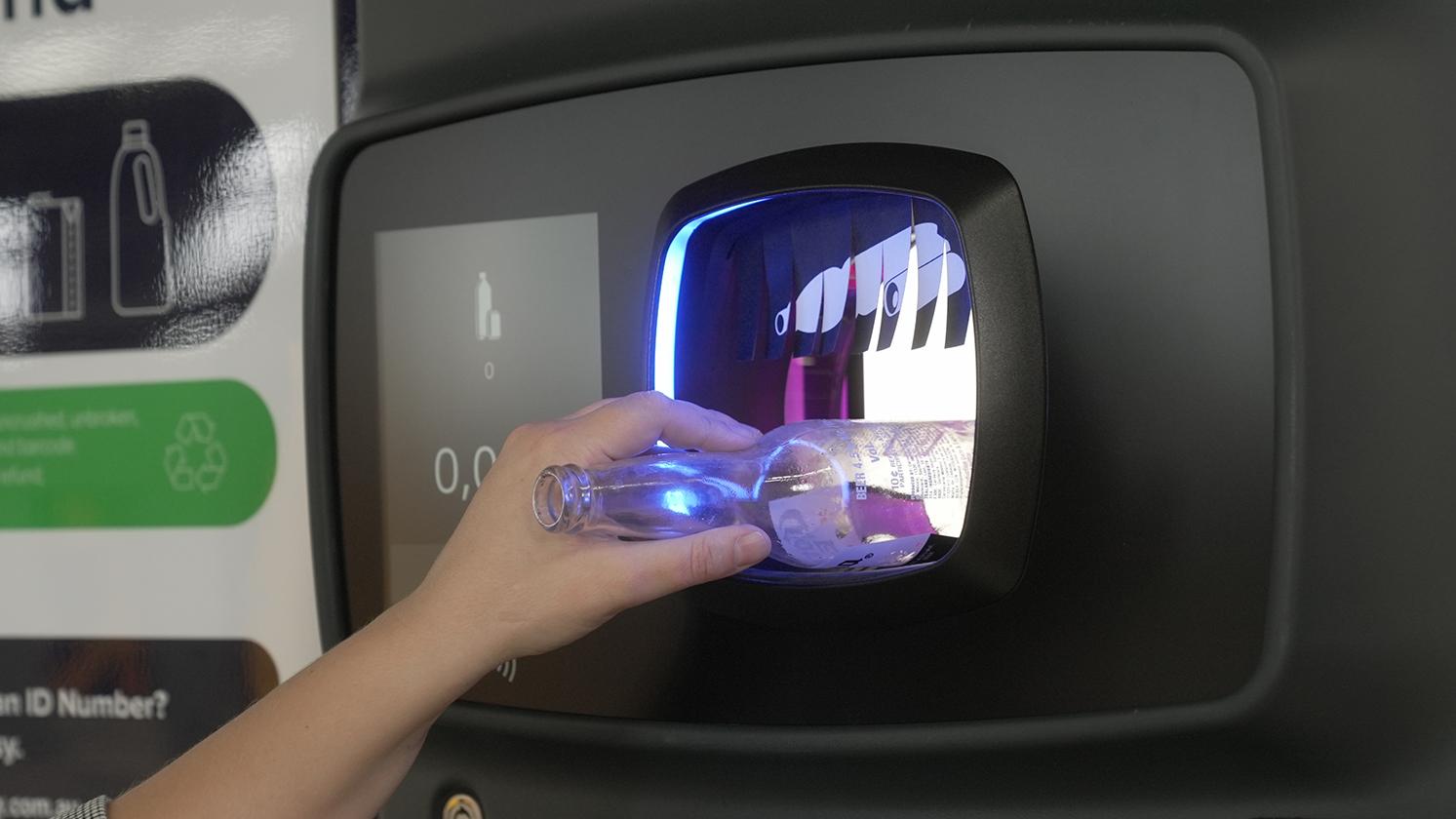

CDS

Visy is a network operator for Victoria's Container Deposit Scheme (CDS Vic).

Sustainability

Sustainability has been at the heart of our business since we began.

Our latest news

‘I wanted to step up’, why site manager Lauren joined Visy

After roles in operations, human resources and management, Lauren Rossi wanted to take the next step in her career.

Learn More about ‘I wanted to step up’, why site manager Lauren joined VisyVisy hits milestone on way to industry-leading target

We have hit a new high—achieving an average of 63% recycled glass in our packaging across Austra

University student’s site visit inspires career at Visy

Find out why Kiana was inspired to join us after a visit to our integrated materials recovery facility and paper mill on Gibson Island.

Learn More about University student’s site visit inspires career at Visy

‘Everyone brings a plate’, culture key for shift manager

Clair Talady, the Afternoon Shift Manager at Visy’s Hemmant box factory, says the site culture is a key reason why Visy is a great place to work.

Learn More about ‘Everyone brings a plate’, culture key for shift managerVisy’s new retail paper bags a win for shoppers and Australian manufacturing

Visy is now making recyclable paper bags for retailers with Australian made paper at its manufacturing plant in Reservoir in Melbourne’s north.

Learn More about Visy’s new retail paper bags a win for shoppers and Australian manufacturing